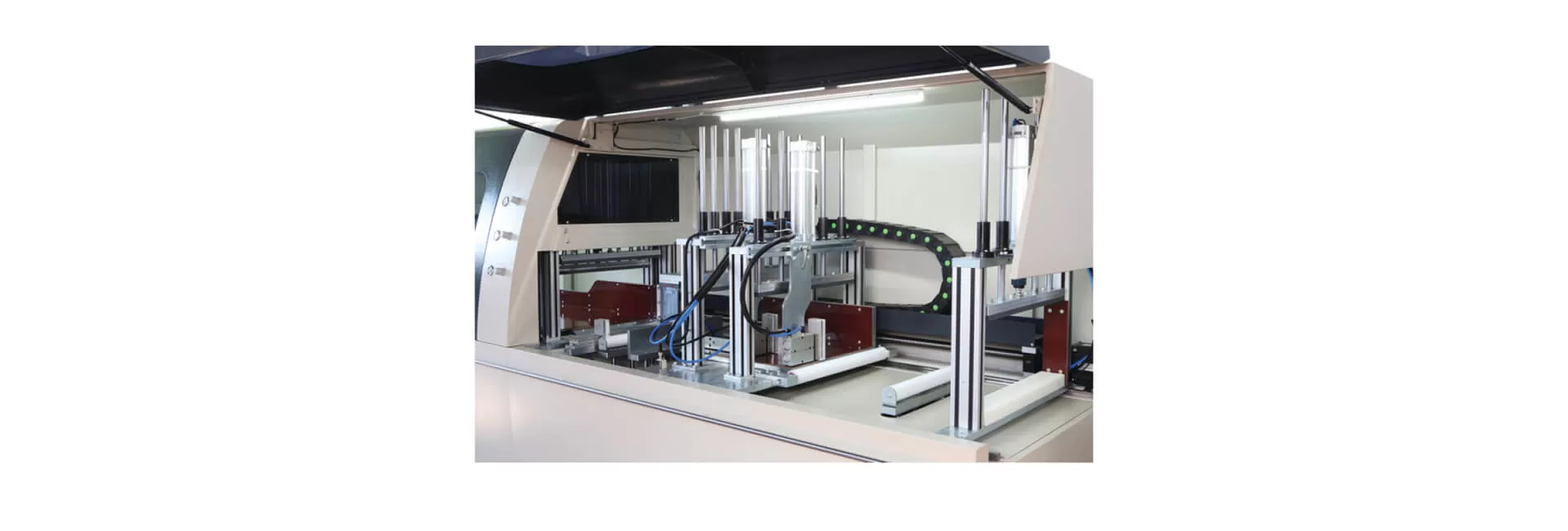

AS 499 Automatic Cutting Saw for Industrial Profiles

Product Properties

It is a radial saw automatic cutting machine specially designed for slicing large aluminum profiles.

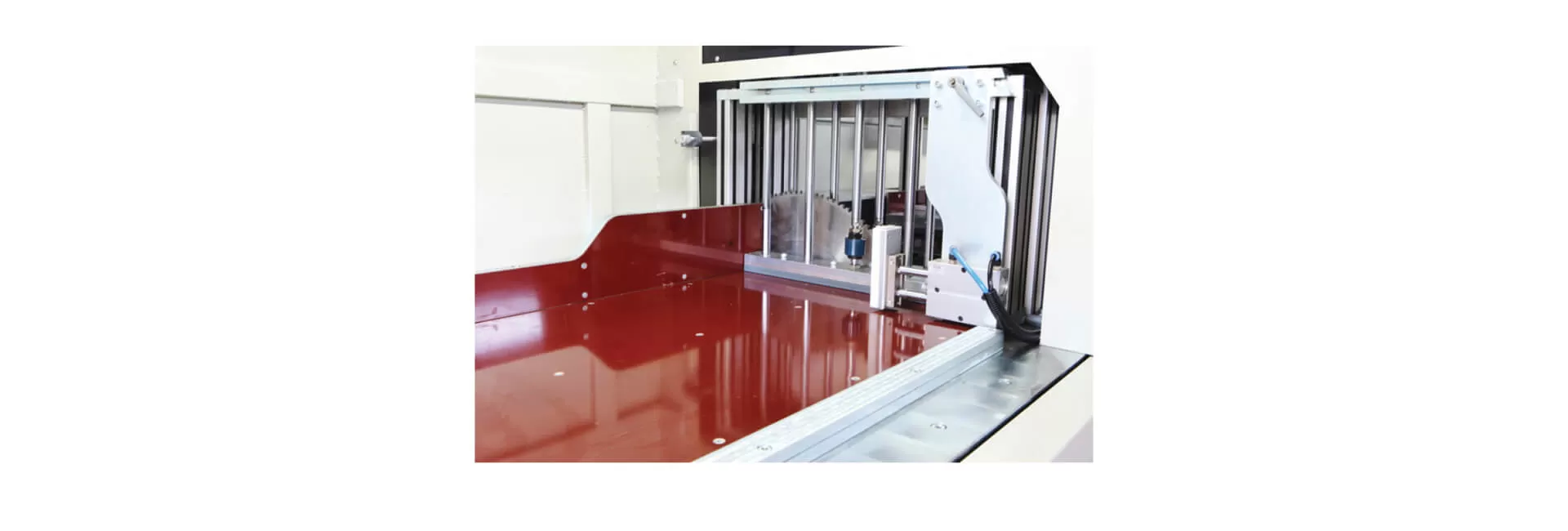

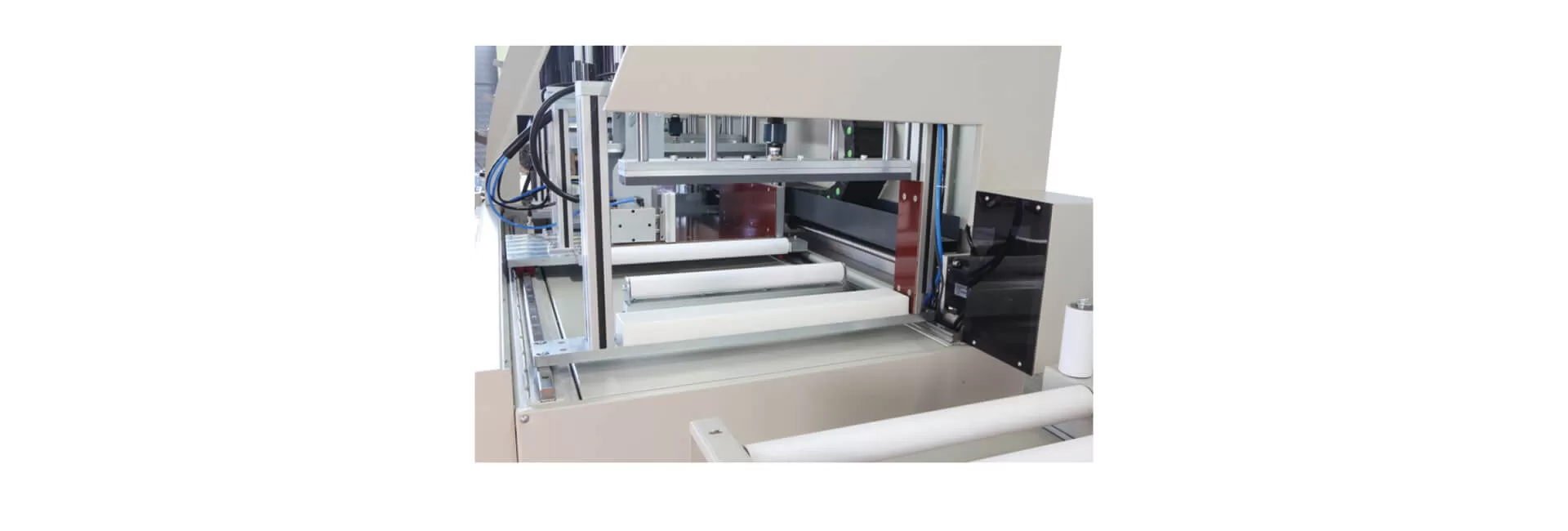

The profiles are loaded into the machine in a length of 6 meters, the machine automatically feeds them with the servo motor mechanism in short dimensions given via PLC control and cuts them with the radial moving saw connected to the servo motor mechanism and the table is opened while the saw is going back to reduce the marks on the cut surface.

There is a standard 700 mm saw attached to the machine.If desired, saws of different sizes up to 350 mm can also be connected.There is a huge 11 kW cutting motor that can be adjusted from 0-4,000 rpm depending on the saw size.Depending on the wall thickness of the profile to be cut and the degree of hardness of the material, the feeding speed and speed of the saw can be adjusted from the control panel; can be memorized according to the type of profile.

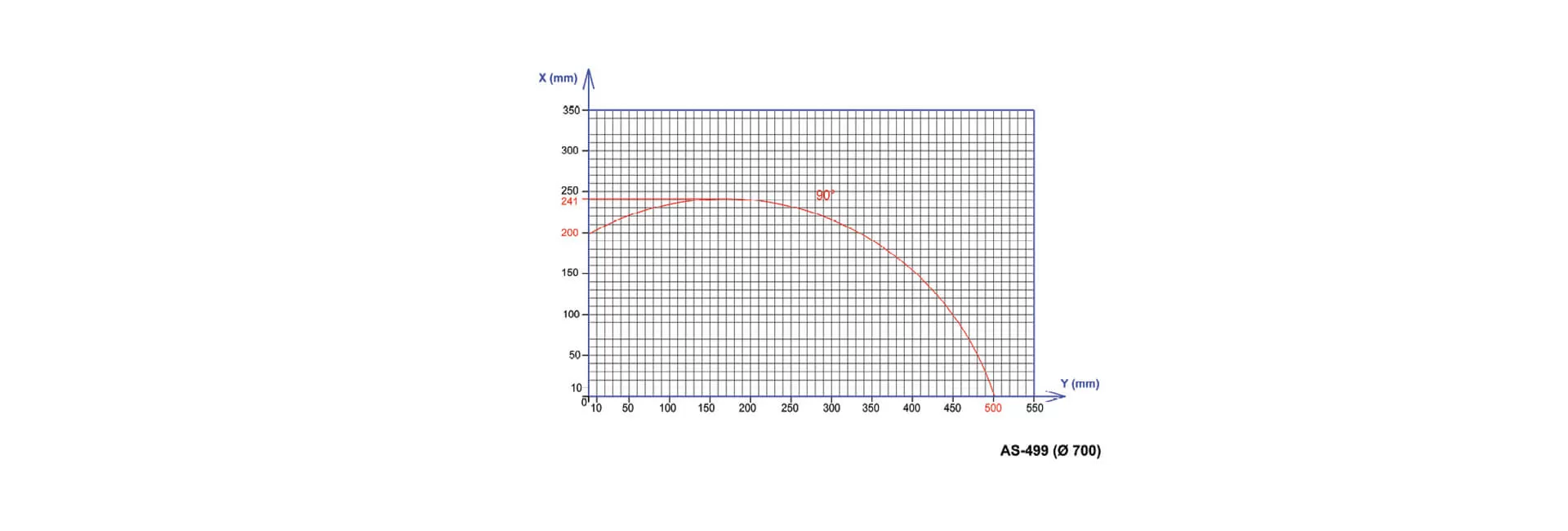

According to the size of the cut profile, the parking position of the cutting saw and the point at which the cutting ends are adjusted according to the minimum time loss thanks to the servo motor saw mechanism; memorized.

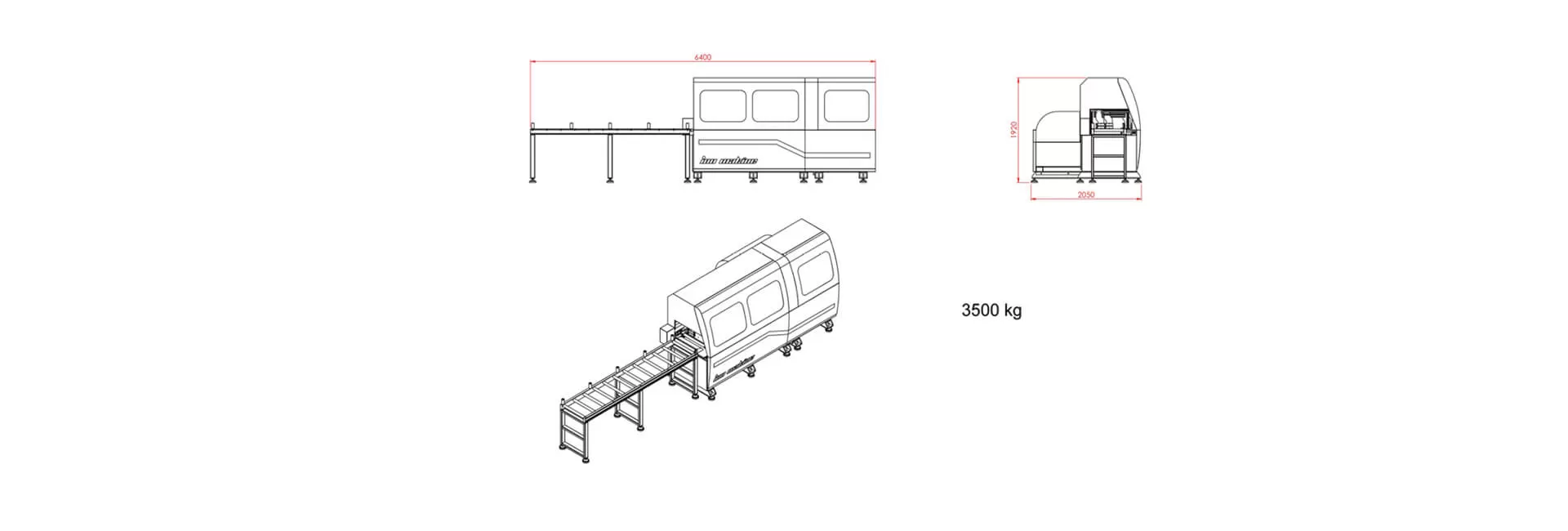

The maximum length that the sliding system with a servo can drive is 1,200 mm.The largest width that the servo saw sliding system can cut with a 700 cm saw is 500 mm.There are 9 different compression units for compressing the profile, resulting in a ricid profile compression and the highest level of precision.Cutting tolerances are 0.1 mm.Next to the machine, a 3-meter conveyor, machine protection cover and emergency stop buttons are standard equipment for feeding the profiles.

Main Body

Welded steel frame normalized by heat treatment.

The main body of the machine is machined in the 5-Axis CNC Steel Machining Center.

The entire body is painted with electrostatic powder paint.Mostly all mechanical parts are machined in our own cnc machining centers or machined on cast material.

During the design process, our design team prioritizes the ease of use and ergonomics of the operators’ machines.

In the mechanical structure, not only steel and aluminum are used; at the same time, fiberglass casting parts are also used to reduce the weight of the processing bridge and give the machine a more aesthetic appearance.

Standard Equipment

10.2″ TFT-LCD Touch panel.

PLC Control system + 99999 pcs cutting memory.

700 mm saw.11.0 kW, 4,000 rpm saw motor.

Ability to adjust the saw speed from the control panel from 0-4.000 rpm with servo inverter.

Automatic cooling of the saw with a spray lubrication unit.

The radial (walking) saw movement is performed by servo motor, after the cutting is finished, the table is opened, the profile is pulled back and the saw turns back empty.

Protection cover with manual movement.

4 clamping units consisting of horizontal and vertical profile clamping units and vertical and yacht compression units on either side of the saw.3 meter hopper.

Product Reviews

There is no review yet.

Add a Review