CNC Panel Processing

- CNC Profile Machining

- CNC Panel Processing

- Aluminum Profile Cutting Saws

- Copy Routers | End Milling

- Measurement System

- Corner Press

- All Products

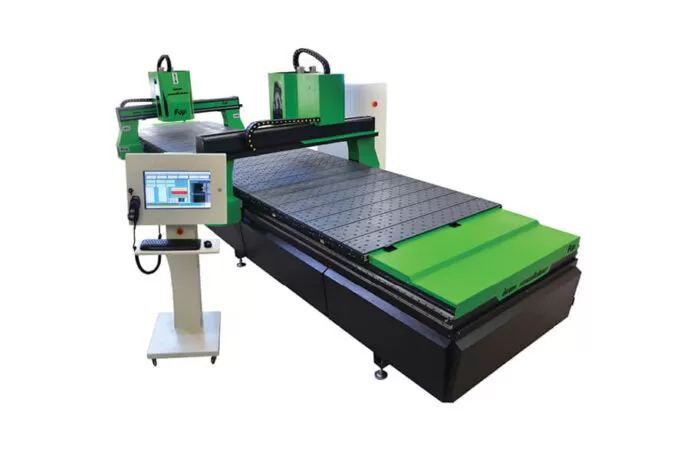

INO XX 9900 Double Bridge CNC Panel Machining Center

More Info

INO XQ 1665 Double Station CNC Panel Machining Center

More Info

INO XT 1665 Double Station CNC Panel Machining Center

More Info

INO XQ 1640 CNC Panel Machining Center

More Info

INO XT 1640 CNC Panel Machining Center

More InfoCNC Panel Machining Centers

The most effective way to carry out panel production at high speed and efficiently is undoubtedly to use a good CNC panel machining center. In the manufacturing processes, these centers perform cutting, dimensioning and similar works with high efficiency. In addition to metal boards, it is possible to process composite, wood or plastic panels in these centers. The machine length is different in these centers, which produced in accordance with different panel processing needs. Panel production is easier with a machining center suitable for the size of the panel that the manufacturer processes. Machining centers can also have vacuum tables or milling heads. The operating speed varies according to the thickness of the panel. CNC panel machining centers with their different varieties are already one of the important components of many production processes.

With CNC systems, the use of which is becoming increasingly common in the manufacturing sector, it is possible to increase productivity and quality in many subjects today. Thanks to the programming on the computers mounted on the CNC machine, the need for human labor reduced. At the same time, operator errors minimized. As it is known, panel processing processes works that require heavy effort. As the length and weight of the panel to be cut increases, the operations become more difficult. However, the works that will take hours or even days to be done manually finished in a much shorter time thanks to CNC panel machining centers. Thanks to computer-aided automation systems, panel processing takes place with zero errors. One of the most effective ways to speed up panel production is to use dual station CNC panel machining centers. In these centers, it is possible to reach the manufacturing capacity of two machines with the same characteristics.

CNC Automation Solutions in Panel Machining Processes

CNC panel machining centers do not consist of a single machine. These tools have integrated solutions that incorporate many different machine functions. Regardless of the type and characteristics of the panels to be processed, it is possible to get the most successful results in panel processing with CNC automation solutions. Aluminum composite panels, for example,easily processed thanks to these solutions. CNC aluminum composite panel sizing machine is an important tool in this field. In centers with smart table system, all processes take place faster. In addition to aluminum panels, steel composite, HPL compact laminate or acrylic panels also easily finished in CNC panel machining.Vacuum tables give advantage to these centers in panel processing processes.

In CNC panel machining centers, vacuum tables have a segmented structure. In this way, they can perform more precise machining on small parts. It is possible to control each of the vacuum chambers separately. Special programs to be used by the operator ensure optimization of panel processing processes. The automatic vacuum opening and closing system on the machine helps the machine to work without losing speed. On the other hand, the smart table system also increases the speed of work. But the speed of the center varies according to the size and thickness of the panel. Adjustments to the CNC control panel are important in such cases. Especially when processing panels of MDF, wood and the like, it is necessary to pay attention to the dimensions and thickness. The net machining length for CNC panel machining centers varies from 4,000 to 10,000 mm.

CNC automation solutions are important for capacity as well as size. It is necessary to use the appropriate programs and commands for machining high-capacity CNC panels at once. Thanks to the automation systems that provide movement in 3 axes, it is possible to reach high production quantities at once. With bridge systems with a dynamic and rigid design, these products reduce the scrap rate and provide cost control. To prevent time loss in tool change, the magazine unit on the bridge is useful. With its special tool cooling system, user-friendly control screen and other features, CNC panel machining centers offer the possibilities of technology to the service of the enterprise.

Ino Machinery CNC Panel Machining Centers and CamBOX Software

CNC machine systems are one of the most important components of manufacturing processes in many different areas today. It is possible to see these machines in almost every kind of machining process. As Ino Makine, we have been one of the few companies in our country in the field of CNC machines since 2010. We meet the needs of CNC profile machining machine, panel machining center, metal processing center in many sectors. Our factory, which serves in Bursa Kestel, raises the standards in CNC machines and systems by taking advantage of advanced technology. Moreover, our products increase user satisfaction not only with their technical hardware but also with their software. On the hardware side, we provide direct management of tool movement and operation of machine components with the machine operation panel. On the software side, we optimize business processes. In this way, we ensure that businesses have access to the solutions that best suit their needs.

Our self-developed CamBOX software is a special software that offers optimized solutions in CNC panel machining. As a matter of fact, thanks to this software, it is possible to easily perform all kinds of panel processing processes. With CamBOX you can make many things easier not only in sheet processing, but also in drawing and design processes. For example, you can throw DXF drawings directly into the program and continue working on them. CamBOX’s machining optimization recognizes the machining lines as different planes and determines the toolpaths accordingly. Thanks to this software, it is possible to create an optimization list for all wastes by entering the waste dimensions in panel processing. Macros specific to the construction sector are another important convenience. It is also possible to create various macros in different areas.

We Grow Your Goals with Ino Machinery Privileges

Today, CNC machining centers are attracting attention in many areas from contract companies to industrial production facilities. When it comes to efficiency and speed, CNC panel machining centers with dual station or double bridge feature are more popular. As a result of the reflection of technological developments on manufacturing processes, interest in manual labor processes decreases. Traditional milling or turning works, groping panel cutting or sizing reduce the competitiveness of companies. However, in order to gain a competitive advantage with CNC production technology, special attention should be paid to brand selection. The types of CNC machines you use must adapt to the solutions required by the production and assembly line. It should take advantage of the latest technologies on the hardware and software side. As for the price, it should offer a cost advantage.

As Ino Machinery, we have met the needs of many enterprises in CNC machines since 2010. We have enabled them to grow their targets with CNC panel machining centers and other products. We have increased their competitive potential. In processes such as milling, drilling, turning, etc., we have freed them from traditional methods and low technologies. Our automatic vacuum opening and closing system, smart table, CamBOX software and other solutions have prevented loss of productivity in production processes. Our welded steel chassis products normalized by heat treatment have provided the same quality usage experience for many years. The fact that all bodies were coated with electrostatic powder coating reduced the health risks. On the other hand, our technical support services facilitated the solution of problems in after-sales processes.

If you have not yet met the privileges of Ino Machinery, you can start to meet immediately. You can contact us for CNC panel machining centers that fit your budget. With fast delivery time, reasonable prices and payment terms, Ino Machinery is always with you. To contact us, you can fill out a form or contact us by phone. The message you leave on the contact form is enough for our experts to reach you as soon as possible.